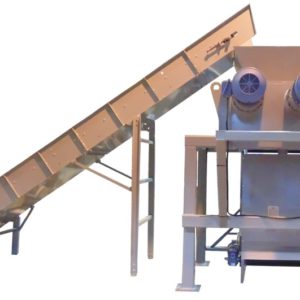

Entexs Midi

$0.00

The ENTEXS MIDI is a complete, turn-key, closed loop, cold ethanol extraction system capable of continuously processing biomass to true full-spectrum crude and/or distillate. The continuous feed carousel system, cascade chillers, and multi-stage wiped film evaporation go from bulk biomass to high quality crude without any operator intervention. This patent-pending system provides unmatched, truly automated hands-free technology.

ENTEXS midi is intended for clients with more than 4500 pounds of biomass per day.