Vulcan CBD Hemp Dryer

$0.00

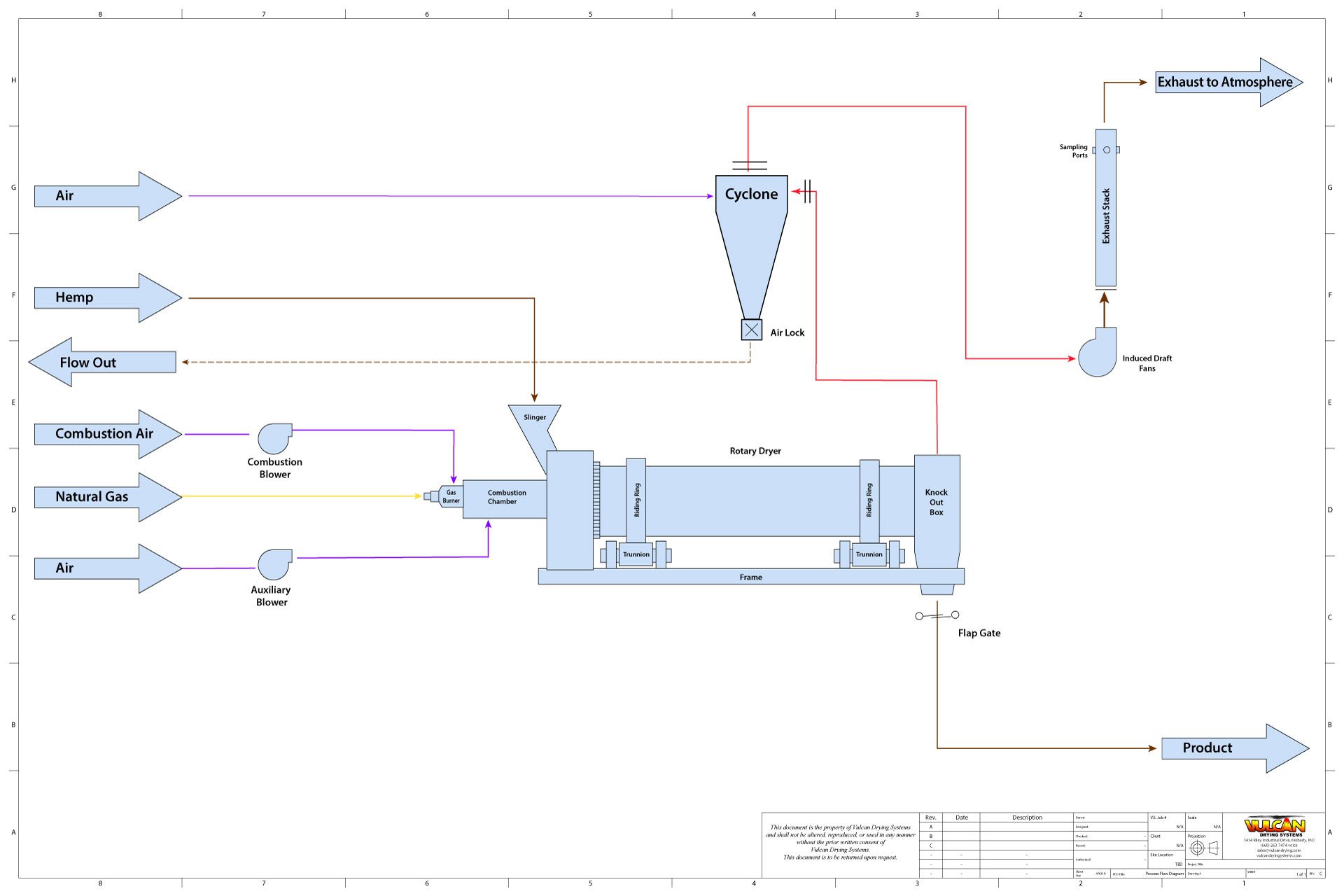

The Vulcan® Drying Systems Hemp Drying System is custom-designed and manufactured to improve a customer’s individual drying needs. These drying systems consist of a correctly sized drum and a burner mounted in a concurrent configuration. Vulcan® Drying Systems Hemp Drying Systems are designed specifically to dry up to 10 tons per hour of hemp with an output moisture content between 10-12%.

Each Vulcan® Drying Systems Hemp Drying System is custom-built for each client. Systems include the following components:

- Feed chute or conveyor

- Rotary Dryer

- Combustion chamber with burner

- Secondary air blower

- Cyclone or Baghouse

- Induced air blower

- Controls

Vulcan Sorting Systems Trommel Screens and Vulcan Sorting Systems Conveyors can be used for sorting and transporting Hemp.